Types of e-sourcing platforms

Practical cases

Advantages of e-sourcing platforms

How E-Sourcing Platforms can improve the service for buyers

How digitalization helps solve the problem of sourcing today

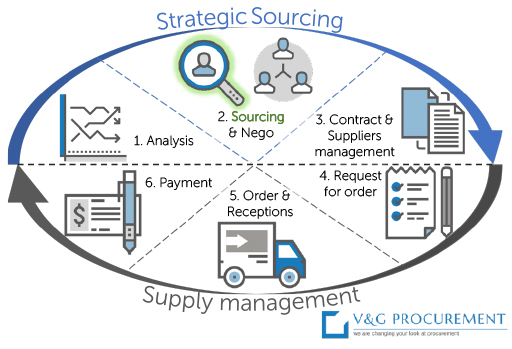

Today, all business processes are subject to digital transformation. Procurement cycle processes are no exception. By investing in digitalization, companies seek to achieve a performance in cost reduction, process acceleration, reduced administration, transparency, ... In this article, we'll not talk about digital transformation in general or list digital tools in the field of procurement, but we will talk about a very important element of the cycle procurement - supplier sourcing.

We often hear the thesis from buyers/purchasers and company executives that E-Sourcing Platforms completely solve the issue of supplier searching. This point of view is actively supported by the opened e-sourcing platforms themselves, as well as developers / vendors of such tools. But how are things really?

To begin with, let's deal with the very concept of "E-Sourcing Platform". For different market participants (depending on their commercial goals, status and market position), the purpose, functionality and capabilities of this tool may differ. There are 6 types of e-sourcing platforms in their various manifestations:

- Opened - platforms with wide access for suppliers and buyers, such as SAP Ariba, Scanmarket, B2B Center, Bidzaar,… The platforms are paid for buyers and in some cases for suppliers.

- Corporate – platforms for procurement in the interests of a particular company or group of companies. Generally free for participating suppliers, although there are exceptions. Corporate e-sourcing platforms can be integrated with opened platforms, they can be implemented on ready-made solutions, but InHouse developments are often found.

- Public - platforms where state institutions and organizations are required to conduct purchases in accordance with local laws.

- Marketplaces for business (Amazon business, Alibaba). In fact, they can also be considered an E-Sourcing Platform, but already with ready-made offers for businesses in popular categories, such as stationery, consumables, and basic raw materials.

- Suppliers' platforms – in fact, these are not procurement platforms, but corporate auctions. They take place in a scarce raw material market (for example, in the “sugar” category).

- Commodity exchanges and platforms operating on the principles of a commodity exchange in the B2B market.

The article will focus exclusively on opened and integrated with opened corporate e-sourcing platforms for business. The owners and sellers of these tools claim to have hundreds of thousands and even millions of active suppliers who "can cover any purchase need" without the buyer needing to search separately. We will illustrate the real possibilities of the e-sourcing platforms on specific procurement cases.

Case 1 "Expendable materials": Purchase of small tools for production

The experience of placing request on opened e-sourcing platforms has shown that only trading companies (distributors, trade houses or even resellers) are registered on the sites. Their very limited number against the background of the complete absence of manufacturing plants made the sample of potential suppliers unrepresentative in terms of market coverage. And their offers, even following the results of the reduction ("playing for a fall"), remained non-competitive, while, for example, the price received as a result of negotiations with the manufacturer turned out to be 2 times lower, which made the transaction outside the e-sourcing platforms more profitable, despite all the operational difficulties of direct contract with the manufacturer.The experience of placing request on opened e-sourcing platforms has shown that only trading companies (distributors, trade houses or even resellers) are registered on the sites. Their very limited number against the background of the complete absence of manufacturing plants made the sample of potential suppliers unrepresentative in terms of market coverage. And their offers, even following the results of the reduction ("playing for a fall"), remained non-competitive, while, for example, the price received as a result of negotiations with the manufacturer turned out to be 2 times lower, which made the transaction outside the e-sourcing platforms more profitable, despite all the operational difficulties of direct contract with the manufacturer.

Case 2 "Contractors": Search for teams of electricians for subcontracting

The general contractor has won a major contract for electrical works in a region with a wide geography, and he has a need for subcontractors. At the same time, in order to meet the economic model, subcontractors had to be represented not by regular intermediaries, but by performers - teams of electricians. It is impossible to find these executors on the e-sourcing platforms. As a rule, these are small companies and individual entrepreneurs, which, in principle, are very difficult to find remotely, even with the help of Internet search engines, since they simply do not have websites, and information on the Internet is often not up-to-date. The search for such suppliers is carried out with the help of business contacts, specialized resources and private ads.

Case 3 "Specific/monopoly market": Network equipment

When equipment manufacturers / vendors are well known, placing a request on the e-sourcing platforms from the point of view of finding suppliers is an action devoid of any added value, a pure waste of time, especially if in the specification is about a specific brand/manufacturer. The maximum that we get in this situation is the "game" of distributors, who do not significantly influence the pricing policy, but can only share their margin, the price reduction in this case will be no more than 2-3% at best. To get the best conditions, it is important to hold a competition among vendors. And at the same time, it is unlikely that vendors will run to register on the e-sourcing platform, since for them this is also an action devoid of any commercial interest. With a limited list of 2-3 manufacturers, direct iterations are shorter, more efficient and do not require additional payment to the intermediary.

Case 4 "Strategic procurement": Raw materials for production

No matter how many responses a search on the e-sourcing platforms gives, it will never be enough for a strategic procurement. The goal of strategic procurement is to find the best supplier(s) in the Market (sometimes not only local but also global), and the maximum that allows us to see various e-sourcing platforms today is only a small segment of the market of suppliers registered and operating on the platform, who have you can only place orders for a one-time or low-value purchase by “comparing 3 commercial offers”.

For strategic procurement, it is important to include all search tools, since we can talk about thousands of tons of purchased products per year and millions of USD. And each percentage of savings received as a result of a well-built sourcing strategy is expressed in huge absolute values for the company and significantly affects the cost of products.

Needless to say, with such volumes, suppliers of raw materials, which are often traded on commodity exchanges and can be in short market, in principle do not consider their participation in tenders, and even more so at the e-sourcing platforms, unless it is an auction, where the sale is carried out to the customer, who will offer the most high price (real case). But this is certainly not what buyers use e-sourcing platform for.

Case 5 "Analysis of proposals": Logistics/transport services

Until recently, e-sourcing platforms offered us to compare and select suppliers solely on price, when all other criteria are clearly defined and fixed for all participants. Needless to say, in this case, the customer often missed important parameters (for example, operational KPIs and methods for their control, payment terms, etc.), and also excluded the possibility for suppliers to offer different technical solutions for the same need. Today, the standard e-sourcing platforms tools allow you to compare the cost of a lot (or separate elements) from suppliers A and B, even taking into account some quality parameters, but this is not always enough. In the case of transport logistics of a large trading company, for each of the 400 directions for delivering goods to points of sale, it was necessary to choose the best carriers from almost 200 declared participating companies and, taking into account quality criteria, allocate quotas for transportation. As a result, 70 suppliers with distributed quotas were selected and spot rates were determined for each direction.

None of the existing public platforms has analytical tools for solving such problems. And corporate e-sourcing platforms require serious custom improvements, moreover, for each category strategy (which still tend to be reviewed regularly).

Supplier selection may also include a complex algorithm for comparing total cost of ownership (TCO), comparison of different use cases such as acquisition, rental / leasing or purchase of XaaS (anything-as-a-service), including an estimate of the net present value (NPV). And in some cases, the e-sourcing platform does not even implement an elementary tool for comparing offers, taking into account the terms of payment and the cost of capital (WACC).

Case 6 “Rare or unique product or service”: Railroad crossing maintenance service

The commercial company organized the entrance to its territory through several railway lines and built a crossing. The sourcing for a service and maintenance company on various opened e-sourcing platforms gave a zero result. This is another illustration of how Google does a better job of finding a supplier than any e-sourcing platform. As in the case of manufacturers or sellers of in low supply goods, it is unlikely that suppliers of a specific or highly specialized product will go on a mass offer of their services on the e-sourcing platforms.

Thus, today traditional digital sourcing tools do not solve the problem of suppliers searching in the context of professional procurement, which, however, coincides with the opinion of a number of buyers that place their purchases on the any e-sourcing platforms. So far, buyers still have to look for suppliers in the old-fashioned way and, if the procurement procedure requires it, convince or force them to register on the e-sourcing platform.

There is another disadvantage: the lack of a representative sample of suppliers or their low response to the e-sourcing platform can become the subject of manipulation by an unscrupulous buyer to justify purchasing from a specific “single supplier”.

Advantages of e-sourcing platforms

Firstly, in any organization there are a large number of low-value purchases, when it is not advisable to use the resources of qualified buyers, since the entire selection of a supplier can be reduced to a “comparison of 3 proposals”. Having determined the level for such purchases (and prescribing them in the procedure), they can be delegated to order managers, internal customers, or outsourced.

Secondly, it is much more convenient to carry out a reduction on the platform (eAuction) than to make calls and send letters to suppliers.This is especially convenient when choosing a “short fixation” strategy in volatile markets, when the buyer forms a pool of suppliers authorized for a certain period (prequalified according to a number of parameters), but without distributing the volume of future purchases. As a result of a short eAuction, the order is placed with the supplier from the pool who offered the best price at the moment.

Thirdly, an e-sourcing platform ensures the transparency of the supplier selection process, and corporate e-sourcing platforms allow you to implement the procedure into a tool and guarantee compliance of the procurement process.

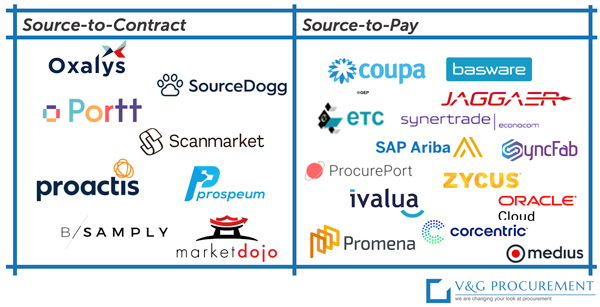

And fourthly, e-sourcing platforms can be integrated with a range of additional procurement tools: from contract management (S2C) including EDI, to the implementation of a full transaction cycle to payment (S2P).

At the same time, the sourcing function itself in these tools implies only the selection of suppliers from the existing list, but they are not tools specifically for searching suppliers, and the e-sourcing platform itself is not a guarantee of procurement on the best commercial terms. The reason for this is that today the platforms are waiting for the suppliers themselves to come and register, or they will be brought by buyers.

How E-Sourcing Platforms can improve the service for buyers

Need to think about ways to encourage suppliers to come to the platform, register and actively respond to inquiries, especially in the situations described in the case studies. And in order for suppliers not to lose interest in the site, it is important:

- 1. Develop a customer base, analyze categories and volumes of purchase requisitions, and provide analytics. The supplier may not understand why he should go to the e-sourcing platform if there are no customers/requests in the area of his products or services.

- 2. Make access and work on the platform free for suppliers in any of its manifestations. The beneficiary of the price reduction is the company-buyer and it is logical that its pays for the services of the platform, and the supplier "pays" his part in the form of a price reduction, which works for the attractiveness of the platform. However, today even some of the platforms that promise free participation of suppliers actually charge a “winning” fee, but this is still the same participation fee, because even if the customer declares the supplier the winner in the competition, this does not guarantee the latter a contract. It is logical that the need to pay reduces the motivation of suppliers and, as a result, market coverage, as well as the number of responses, thereby limiting competition.

- 3. Simplify registration. In a number of corporate e-sourcing platforms, the process of registration and prequalification is identical for all suppliers and categories, which sometimes requires from 0.5 to 2.0 man/day for the supplier to complete this procedure. Professional buyers know that detailed qualification of potential supplier is not always appropriate - it depends on the category and type of procurement, the cost of RFx, etc. Registration should be very simple, and prequalification should be specific to the category.

- 4. Set up the nomenclature.. Sometimes suppliers who try to register on the e-sourcing platform cannot find the category in which they provide their goods or services. Or they are required to provide documents that are not applicable to their activities. Dear platform's teams, there are no such nomenclature categories as “other”, “miscellaneous”, just “services”, “low-value purchases” or “outsourcing” - these are “garbage bins” where irrelevant applications are poured into suppliers. There is nothing to be surprised that there are no responses to requests. Professional buyers or purchasing consultants will help you to correctly compile the nomenclature.

- 5. Develop analytical tools for evaluating proposals. At least at the level of common procurement scenarios: evaluate the impact of payment terms, TCO, NPV.

How digitalization helps solve the problem of sourcing today

The Procurement need is that they want to get the best response from the Market to their request, while the administrative and time costs must be optimized and matched to this task.

To solve the sourcing problem of new suppliers (supplier scouting), today there are tools for proactive discovery and verification of suppliers, materials and services from all available sources (following the example of Scoutbee). The principle of their work is based on a search engine and a machine learning algorithm with AI elements. These tools create the widest possible database of suppliers and universal catalogs for materials and services. This data base is constantly supplemented and the relevance of information is maintained.

There are other tools that allow you to use well-developed supplier databases joined with S2P functionality. Primary sourcing is supported by external experts who specialize in sourcing/purchasing. A number of large companies have a practice of creating an internal sourcing team.

Sourcing is important lever in cost reduction. In our practice, the cost of high-quality sourcing pays off 5 times or more. The involvement of independent experts will allow assessing the current level of use of this lever and identifying ways to improve its performance.